Laser Engraving Tech in 2025: The Ultimate Guide to Incisore Laser & Taglio Laser

Laser technology has soared in both industrial and lifestyle applications, transforming how we personalize everyday objects and manufacture precision parts. Two essential processes, incisore laser (laser engraving) and taglio laser (laser cutting), have reshaped sectors from automotive to boutique crafts, making high-quality, automated, and repeatable designs standard. Whether customizing gifts or producing complex metal parts, this technology blends cutting-edge science with artistic flair.

In 2025, advances in speed, accuracy, and accessibility have made laser tech indispensable. From hobbyist workshops to industrial setups, anyone can leverage laser tools to innovate. This article explores the technology’s capabilities, highlights real-world applications, and shows how even small businesses can benefit from precise laser work.

What Is Incisore Laser & Taglio Laser?

Incisore laser refers to engraving precise patterns or text on materials by vaporizing surface layers with a focused laser beam. Taglio laser, in contrast, cuts straight through materials, creating clean, sharp edges with high thermal precision—ideal for metal, wood, plastic, or acrylic. Both are powered by systems like CO₂, fiber, or UV lasers, controllable to micron accuracy.

How Laser Engraving & Cutting Works

Laser systems consist of a laser source, beam delivery, focusing optics, and a computer-controlled motion system. The beam’s intensity, speed, and path are programmed to create detailed engravings (incidere) or clean cuts (taglio). Advanced models use galvo mirrors for rapid beam steering or gantry systems for larger areas.

Laser precision outperforms mechanical techniques, enabling fine fonts, complex logos, or customized artwork without physical contact or tool wear. And as IoT and smart software evolve, laser engraving and cutting become even more efficient and automated.

Key Applications in Industry and Everyday Life

1. Personalized Lifestyle Items

From engraved wooden cutting boards to custom phone cases, incisore laser adds unique flair to gifts and décor. Sleek glass engravings or plush leather personalization pave the way for your creativity to shine, perfect for Etsy shops or small online brands.

2. Signage and Promotional Goods

Laser cutting creates sharp acrylic signage, metal nameplates, or branded keychains. Its speed and repeatability make it ideal for bulk promotional needs.

3. Precision Industrial Manufacturing

In electronics, automotive parts, and medical devices, micron-level accuracy from taglio laser enables intricate components that meet high-performance standards, minimizing material waste and post-processing.

4. Fashion, Jewelry & Accessories

Laser cutting transforms leather, fabrics, and metals into delicate patterns for apparel, jewelry, or watch parts. Meanwhile, engraving personalizes pieces with names, dates, or intricate designs.

Benefits of Laser Over Traditional Methods

- Unmatched Precision: Micron-level control outpaces manual etching or CNC milling.

- Versatility: Switch quickly between engraving and cutting on the same setup.

- Low Maintenance: No dies or blades to replace—just occasional mirror and lens care.

- Speed & Automation: Suitable for high-volume order fulfillment with consistent results.

- Material Efficiency: Reduces waste with narrow cut kerfs and precise engraving.

Introducing Premier Laser Engravers

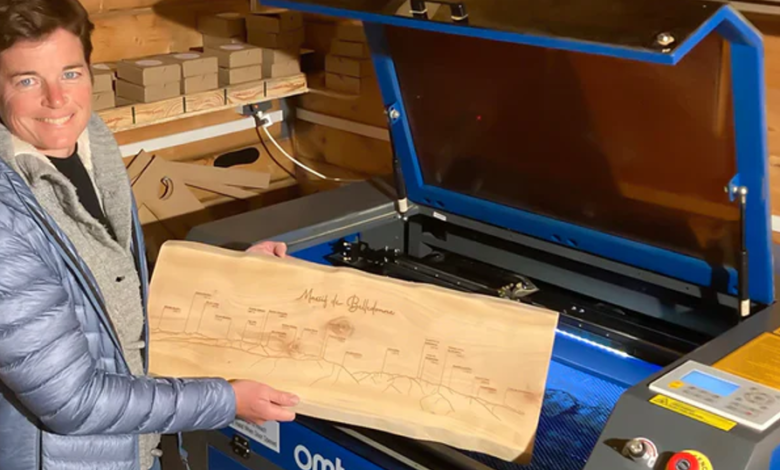

One standout collection is the incisore laser series by OMTech, featuring CO₂ systems optimized for both engraving and cutting tasks. These machines offer strong warranties, streamlined software compatibility, and built-in safety features—ideal for creators and manufacturers.

Lifestyle Applications That Enhance Everyday Life

Home Decor & DIY Projects

Wooden coasters, framed quotes, or mirror etchings all achievable at home. Hobbyist engravers are affordable, letting anyone explore creative laser cuts and engravings.

Gift & Wedding Personalization

From engraved wine glasses to laser-cut wedding favours, these technologies raise craftsmanship to a personal level.

Educational Tools & DIY Kits

Makerspaces and schools now include laser cutters to teach design, STEM skills, and digital fabrication, preparing the next generation of creators.

Tips for Getting Started

- Choose the Right Laser: Use CO₂ lasers for wood, acrylic, leather; fiber lasers for metals.

- Learn Software: Tools like LightBurn offer advanced control for engraving and cutting.

- Prioritize Safety: Work in ventilated spaces, use proper exhaust, and follow laser-class safety standards.

- Optimize Settings: Test power, speed, and frequency on scrap pieces before final jobs.

- Source Quality Materials: Use laser-compatible media to avoid toxic fumes or safety issues.

Future Trends in Laser Tech

- Compact Devices: Desktop engravers under $500 continue to grow in popularity.

- Multi-Material Cutting: Smart systems can switch between materials seamlessly.

- AI-Assisted Setup: Cameras and AI help align and preview laser jobs before cutting.

- Integration with 3D Printing: Laser heads nozzle-mounted, enabling high-res hybrid prints.

- Expanded IoT Monitoring: Real-time diagnostics and remote job execution via the cloud.

FAQs

What’s the difference between incising and cutting lasers?

Incising (incisore laser) vaporizes surface layers without passing through the material, while cutting lasers (taglio laser) go fully through to separate pieces cleanly.

Which materials are best for laser processes?

Wood, acrylic, leather, glass, ceramics, and fabric suit CO₂ laser engraving/cutting. Metals and plastics often require fiber or UV lasers for clean, precise results.

Is laser engraving safe to do at home?

Yes, with proper ventilation, eye protection, and a Class I enclosed machine or Class IV safety protocols, it’s safe for DIY use.

How fine can laser engravings be?

Modern laser systems offer resolutions of up to 1,000 DPI or better, making tiny, detailed fonts and fine artwork possible.

Conclusion

The surge in laser engraving (incisore laser) and laser cutting (taglio laser) is revolutionizing both industry and lifestyle. From personalized home décor and wedding trinkets to precision-engineered components, laser systems offer unmatched versatility, precision, and efficiency. As tools like OMTech’s CO₂ machines become more accessible, creators and businesses can integrate laser tech into everyday workflows, enhancing creativity, productivity, and profitability. Whether you’re a hobbyist or a manufacturer, the power of the laser is now in your hands, capable of transforming imagination into a precise, beautiful reality.

If you’re interested in exploring laser software, safety practices, or industrial case studies, just ask. I’d be happy to dig deeper!